Product Description

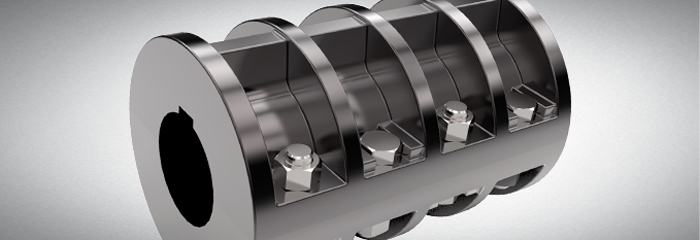

GR-16×27 Clamp Rigid Coupling from HangZhou Suma

Description of GR-16×27 Clamp Rigid Coupling from HangZhou Suma

>The material is aluminum alloy, and the middle bellows is made of stainless steel with excellent corrosion resistance

>Laser welding is used between bellows and shaft sleeve, with zero rotation clearance, suitable for CHINAMFG and reverse rotation

>Bellows structure can effectively compensate radial, angular and axial deviation

>Designed for servo motor stepper motor

>Fastening method of setscrew

Catalogue of GR-16×27 Clamp Rigid Coupling from HangZhou Suma

|

model parameter |

common bore diameter d1,d2 |

ΦD |

L |

LI |

L2 |

L3 |

N |

F |

tightening screw torque |

|

GR-16×27 |

4,5,6,6.35,7,8 |

16 |

27 |

7.5 |

2 |

8 |

13.5 |

3 |

0.7 |

|

GR-20×32 |

5,6,6.35,7,8,9,9.525,10,11,12 |

20 |

32 |

7.2 |

2.8 |

12 |

18 |

3.5 |

0.7 |

|

GR-22.5×34 |

5,6,6.35,7,8,9,9.525,10,11,12 |

22.5 |

34 |

8.05 |

2.8 |

12.3 |

20.2 |

4.5 |

1.7 |

|

GR-25×37 |

6,6.35,7,8,9,9.525,10,11,12 |

25 |

37 |

9.5 |

3 |

12 |

20.2 |

4.5 |

1.7 |

|

GR-32×42 |

8,9,10,11,12,12.7,14,15 |

32 |

42 |

8 |

4 |

18 |

27.2 |

5.5 |

4 |

|

GR-40×51 |

8,9,9.525,10,11,12,12.7,14,15,16,17,18,19,20 |

40 |

51 |

9.5 |

6 |

20 |

34.5 |

5.5 |

4 |

|

GR-55×57 |

10,11,12,12.7,14,15,16,17,18,19,20,22,24,25 |

55 |

57 |

9 |

6 |

27 |

51.9 |

6.25 |

7 |

|

GR-65×81 |

10,11,12,12.7,14,15,16,17,18,19,20,22,24,25,28,30,32,35,38 |

65 |

81 |

19.5 |

7 |

28 |

60.5 |

8.9 |

7 |

|

model parameter |

Rated torque(N.m) |

allowable eccentricity (mm) |

allowable deflection angle (°) |

allowable axial deviation (mm) |

maximum speed (rpm) |

static torsional stiffness (N.M/rad) |

weight (g) |

|

GR-16×27 |

0.8 |

0.1 |

2 |

-0.8 |

20000 |

150 |

8 |

|

GR-20×32 |

1.5 |

0.1 |

2 |

-1.2 |

18000 |

220 |

13 |

|

GR-22.5×34 |

1.8 |

0.15 |

2 |

-1.2 |

16000 |

300 |

22 |

|

GR-25×37 |

2 |

0.15 |

2 |

-1.2 |

15000 |

330 |

30 |

|

GR-32×42 |

2.5 |

0.2 |

2 |

-1.7 |

11000 |

490 |

53 |

|

GR-40×51 |

6.4 |

0.3 |

2 |

-1.7 |

10000 |

530 |

85 |

|

GR-55×57 |

12 |

0.3 |

2 |

-1.7 |

9000 |

860 |

170 |

|

GR-65×81 |

18 |

0.2 |

2 |

-1.8 |

4500 |

900 |

280 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the Torque and Speed Limits of Clamp Couplings in Various Applications?

The torque and speed limits of clamp couplings vary depending on their design, material, and application. Generally, clamp couplings are suitable for a wide range of torque and speed requirements in various mechanical systems. Here are some considerations:

Torque Limits:

Clamp couplings can handle a broad range of torque values, making them suitable for low, medium, and high torque applications. The torque capacity is influenced by factors such as the material and size of the coupling, as well as the clamping force applied to the shaft.

It is crucial to select a clamp coupling that can handle the maximum torque generated in the system during operation. Oversizing the coupling ensures it can safely transmit the required torque without reaching its limits, reducing the risk of premature failure.

Speed Limits:

Similar to torque limits, the speed limits of clamp couplings are influenced by their design and material. In high-speed applications, factors like centrifugal forces and resonance become significant considerations.

Clamp couplings made from high-strength materials like stainless steel or alloy steel can handle higher speeds with minimal risk of deformation or failure. Additionally, precision machining and balancing of the coupling help reduce vibration and maintain stability at elevated speeds.

Application-Specific Considerations:

When using clamp couplings in specific applications, factors like shock loads, reversing loads, and misalignment should be accounted for. These dynamic forces can impact the overall performance and durability of the coupling.

It is essential to consult the manufacturer’s specifications and guidelines for torque and speed ratings. Additionally, engineering calculations and simulations can help determine the most suitable clamp coupling for a particular application.

Professional Advice:

If you are unsure about the torque and speed limits of clamp couplings for your specific application, it is advisable to seek professional advice from coupling manufacturers or engineering experts. They can provide valuable insights and recommend the most appropriate coupling for your requirements, ensuring reliable and efficient power transmission in your mechanical system.

Potential Causes of Failure in Clamp Couplings and Prevention

While clamp couplings are robust and reliable, certain factors can lead to failure if not addressed properly. Here are some potential causes of failure and the corresponding prevention measures:

- Insufficient Torque: If the coupling is not tightened to the recommended torque, it may slip or come loose during operation. To prevent this, always follow the manufacturer’s torque specifications and use a torque wrench during installation.

- Material Fatigue: Repeated load cycles and excessive vibration can lead to material fatigue and eventual failure. Choosing high-quality materials and performing regular inspections can help detect fatigue and replace the coupling before failure occurs.

- Corrosion: In corrosive environments, the coupling’s material may degrade over time, compromising its strength. Using stainless steel or other corrosion-resistant materials can prevent this issue.

- Improper Alignment: Misalignment between shafts can put undue stress on the coupling, leading to premature failure. Properly align the shafts during installation to avoid this problem.

- Overloading: Exceeding the maximum torque or speed limits specified by the manufacturer can cause the coupling to fail. Stay within the recommended operating parameters to prevent overloading.

- Temperature Extremes: Extreme temperatures can affect the material properties and cause the coupling to become brittle or lose its integrity. Select a coupling rated for the operating temperature range of the application.

- Poor Maintenance: Neglecting regular maintenance can lead to undetected wear, damage, or contamination, which may ultimately result in failure. Implement a proactive maintenance schedule and inspect the coupling regularly.

- Foreign Object Debris (FOD): Foreign particles or debris caught between the coupling components can lead to uneven loads and wear. Keep the coupling and its surroundings clean to avoid FOD-related issues.

- Improper Installation: Incorrectly installing the coupling, such as using incorrect fasteners or not following the manufacturer’s guidelines, can compromise its performance and durability. Always refer to the installation instructions and seek professional help if needed.

- Environmental Factors: Consider the specific environmental conditions of the application, such as humidity, chemicals, or abrasive substances, and select a coupling that can withstand these conditions.

By understanding and addressing these potential causes of failure, users can ensure the longevity and reliable performance of clamp couplings in their mechanical systems.

Advantages of Using a Clamp Coupling

A clamp coupling offers several advantages compared to other types of couplings, making it a popular choice in various mechanical systems:

- Easy Installation: Clamp couplings are simple to install and require minimal tools and expertise. The design allows for quick assembly and disassembly, making maintenance and shaft replacement convenient.

- Cost-Effective: With a straightforward design and fewer components, clamp couplings are cost-effective to manufacture and purchase.

- High Torque Transmission: Clamp couplings can handle high torque loads, making them suitable for heavy-duty applications in industries like manufacturing, mining, and construction.

- Zero Backlash: The clamping mechanism ensures a tight fit between the shafts and the hubs, resulting in zero backlash. This feature is vital for applications that require accurate and precise motion transfer.

- Flexibility: Clamp couplings can accommodate different shaft sizes and materials, providing flexibility in system design and shaft compatibility.

- Compact Design: The compact and lightweight design of clamp couplings makes them ideal for applications with space constraints.

- No Lubrication Needed: Unlike some other couplings, clamp couplings do not require lubrication, reducing maintenance requirements and eliminating the risk of leakage or contamination in certain environments.

- High Misalignment Tolerance: Clamp couplings can handle moderate levels of angular, parallel, and axial misalignment, ensuring reliable operation even when shafts are not perfectly aligned.

- Reduced Downtime: The ease of installation and maintenance of clamp couplings contributes to reduced downtime during equipment repairs or replacements.

Due to these advantages, clamp couplings are widely used in various industries and mechanical setups for their simplicity, reliability, and cost-effectiveness in transmitting torque and rotational motion between shafts.

editor by CX 2024-03-15