Product Description

Cast iron emergency pipe leak repair clamp

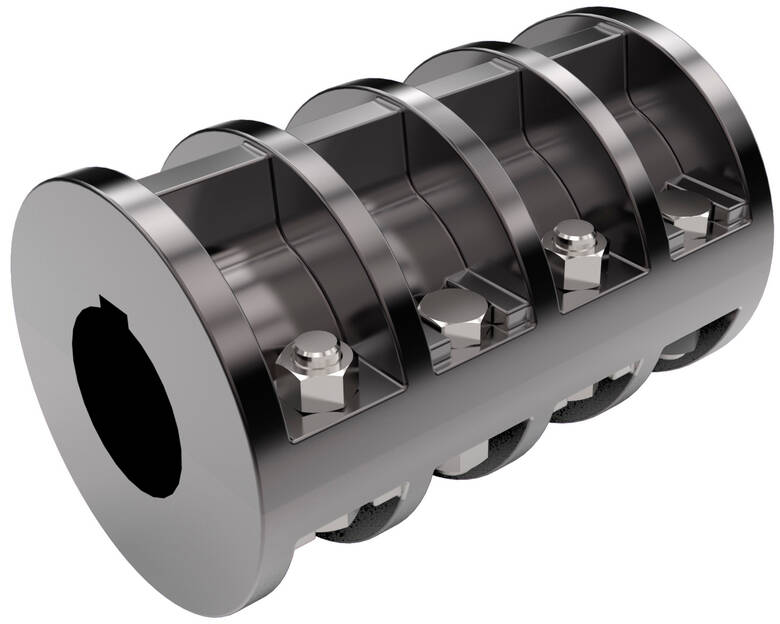

Two-Piece Type Ductile Iron Repair Clamp, split sleeves

1. Product descriptin

- Pipe repair clamp for the quick,safe and permanent repair i the drinking water sector.

- Two-piece design,preferabley made from ductile cast iro.

- Suitable for steel and cast iron pipe

- Nominal sizes: DN40,DN50,DN80,DN1

Workshop:

No.15, Xihu (West Lake) Dis.chuang S &T park, Jiansheng South Street, Chemical district HangZhou, ZheJiang province, China

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1What Industries Commonly Use Clamp Couplings and Why?

Clamp couplings are widely used in various industries due to their versatility, ease of installation, and ability to accommodate different shaft sizes and misalignments. Some of the industries where clamp couplings are commonly used include:

- Manufacturing: In manufacturing industries, clamp couplings are commonly employed in conveyor systems, machine tools, and material handling equipment. They provide a reliable and flexible connection between shafts, allowing for smooth power transmission and easy maintenance.

- Agriculture: Farm machinery and equipment often use clamp couplings to connect power take-off shafts, ensuring efficient power transfer from the tractor to various implements like mowers, balers, and harvesters.

- Food and Beverage: The food and beverage industry requires couplings that are easy to clean and maintain. Stainless steel clamp couplings are commonly used in food processing equipment due to their corrosion resistance and hygienic design.

- Packaging: Packaging machinery often uses clamp couplings to connect rotating components, such as rollers and conveyors, ensuring precise and synchronized movement during the packaging process.

- Oil and Gas: In the oil and gas industry, clamp couplings are used in various applications, including pumps, compressors, and drilling equipment. Stainless steel clamp couplings are favored in offshore and corrosive environments.

- Automotive: In automotive manufacturing, clamp couplings find applications in power transmission systems, steering columns, and drivetrain components.

- Marine: The marine industry often employs clamp couplings in propulsion systems and auxiliary machinery, especially when corrosion resistance and reliability are critical.

- Pharmaceutical: Pharmaceutical manufacturing equipment requires couplings that meet stringent hygiene standards. Stainless steel clamp couplings are suitable for pharmaceutical applications due to their cleanability and resistance to contamination.

- Mining: Mining machinery relies on robust and reliable couplings to withstand heavy loads and harsh operating conditions. Clamp couplings are commonly used in conveyors, crushers, and other mining equipment.

The widespread use of clamp couplings across industries can be attributed to their ability to provide a secure and backlash-free connection between shafts, accommodate misalignment, and handle varying torque and speed requirements. Additionally, their simple design and ease of maintenance make them a popular choice in numerous industrial applications.

Use of Clamp Couplings in Horizontal and Vertical Shaft Applications

Yes, clamp couplings can be used in both horizontal and vertical shaft applications. The design of clamp couplings allows them to provide secure and reliable shaft connections in various orientations, making them versatile for different mechanical systems.

Horizontal Shaft Applications: In horizontal shaft applications, clamp couplings are commonly used to connect two shafts in a straight line. They are often employed in conveyor systems, pumps, fans, and other machinery where the shafts are aligned horizontally. The clamping action of the coupling ensures a rigid and balanced connection, transmitting torque efficiently from one shaft to another.

Vertical Shaft Applications: In vertical shaft applications, such as in vertical pumps, mixers, or gearboxes, clamp couplings need to support the weight of the connected components in addition to transmitting torque. The design of clamp couplings with robust clamping screws ensures that the coupling remains securely fastened even in vertical orientations.

Factors to Consider: While clamp couplings are suitable for both horizontal and vertical shaft applications, there are some considerations to keep in mind:

- Load and Weight: In vertical shaft applications, the coupling must handle the weight of the rotating components. It is essential to choose a clamp coupling with sufficient load-carrying capacity to support the vertical arrangement.

- Alignment: Proper alignment of the shafts is crucial for any coupling, but it becomes particularly important in vertical applications to avoid excessive loads and premature wear.

- Material and Environment: Selecting the appropriate material and surface treatment for the clamp coupling is essential, especially if the application involves exposure to harsh environments or corrosive substances.

Overall, clamp couplings are a reliable and cost-effective choice for various shaft applications, and their ability to perform well in both horizontal and vertical orientations makes them widely used in a range of industrial machinery and equipment.

Can Clamp Couplings Accommodate Different Shaft Sizes and Materials?

Yes, clamp couplings are designed to accommodate different shaft sizes and materials, making them versatile for various mechanical applications. The flexibility in shaft size compatibility is one of the key advantages of using clamp couplings.

Clamp couplings typically come in a range of sizes, allowing them to fit various shaft diameters. The clamp design allows for easy adjustment and tightening around the shaft, creating a secure connection. This adjustability makes clamp couplings suitable for connecting shafts of different sizes without the need for precise machining or customizations.

Moreover, clamp couplings can handle different materials used for shafts, including steel, stainless steel, aluminum, and even non-metallic materials like plastics. As long as the shaft material is strong enough to handle the intended torque and load requirements, a clamp coupling can effectively connect the shafts.

When selecting a clamp coupling, it is essential to consider the specific application requirements, including torque, speed, misalignment, and environmental conditions. Properly matching the coupling size and material to the shafts’ specifications ensures a reliable and efficient connection, reducing the risk of premature wear or failure.

editor by CX 2024-04-26