Product Description

Product Description

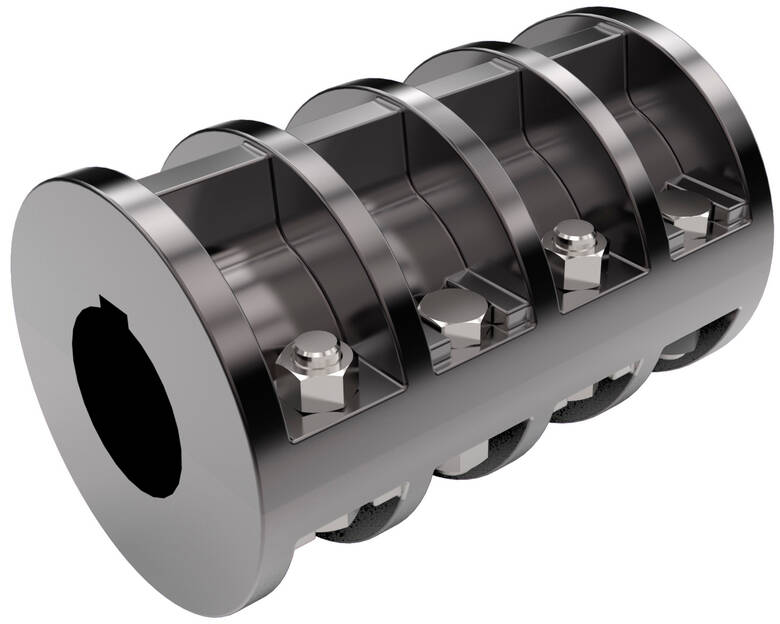

A clamp for the quick repair of pit holes, punctures or splits in steel pipe.Repairs leaks on water,gas,oil and pressure steam lines up to 20kgf/cm2.The features are the same as the pipe couplling except for the working pressure.

Product Parameters

| NO. | DESCRIPTION | UNIT |

| 1 | HOBOND Pipe Repair Clamps 50A For Pipe OD 57-61mm Rubber:EPDM | Pcs |

| 2 | HOBOND Pipe Repair Clamps 650A For Pipe OD 74-78mm Rubber:EPDM | Pcs |

| 3 | HOBOND Pipe Repair Clamps 80A For Pipe OD 87-93mm Rubber:EPDM | Pcs |

| 4 | HOBOND Pipe Repair Clamps 100A For Pipe OD 112-118mm Rubber:EPDM | Pcs |

| 5 | HOBOND Pipe Repair Clamps 125A For Pipe OD 137-142mm Rubber:EPDM | Pcs |

| 6 | HOBOND Pipe Repair Clamps 150A For Pipe OD 165-171mm Rubber:EPDM | Pcs |

| 7 | HOBOND Pipe Repair Clamps 200A For Pipe OD 211-221mm Rubber:EPDM | Pcs |

| 8 | HOBOND Pipe Repair Clamps 250A For Pipe OD 263-273mm Rubber:EPDM | Pcs |

| 9 | HOBOND Pipe Repair Clamps 300A For Pipe OD 314-324mm Rubber:EPDM | Pcs |

| 10 | HOBOND Pipe Repair Clamps 50A For Pipe OD 57-61mm Rubber:NBR | Pcs |

| 11 | HOBOND Pipe Repair Clamps 65A For Pipe OD 74-78mm Rubber:NBR | Pcs |

| 12 | HOBOND Pipe Repair Clamps 80A For Pipe OD 87-93mm Rubber:NBR | Pcs |

| 13 | HOBOND Pipe Repair Clamps 100A For Pipe OD 112-118mm Rubber:NBR | Pcs |

| 14 | HOBOND Pipe Repair Clamps 125A For Pipe OD 137-142mm Rubber:NBR | Pcs |

| 15 | HOBOND Pipe Repair Clamps 150A For Pipe OD 165-171mm Rubber:NBR | Pcs |

| 16 | HOBOND Pipe Repair Clamps 200A For Pipe OD 211-221mm Rubber:NBR | Pcs |

| 17 | HOBOND Pipe Repair Clamps 250A For Pipe OD 263-273mm Rubber:NBR | Pcs |

| 18 | HOBOND Pipe Repair Clamps 300A For Pipe OD 314-324mm Rubber:NBR | Pcs |

Detailed Photos

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

>> “EXCELLENT QUALITY” , “BEST PRICE”, “SOONEST TIME”<<

>> One of the biggest marine hardware wholesaler in china.

>> 15 years of professional reliable service.

>>10000 square CHINAMFG store warehouse guarantee the shortest delivery time

>> Member Of IMPA International Marine Purchasing Association.

Q: What qualifications does your company have ?

A:IMPA Member and IMPA Standardized Products

World Top 10 Ship Chandlers’s Expertised Supplier for 15 Years.

Authorization of “AAA Grade Credit Enterprise” from Government

Q: Can I get qualified products? I do not want any shortage , damaged products

A: Professional Q.C. (quality control) Team & Testing Equipment

Correspondent and Effective CCS, MED, CE Certificates

Exclusive and Famous Brand” KENPO,SEMPO,HOBOND,FASEAL ,GLM”

Q: How long is the delivery time?

A:1~15days Quick Delivery Time .

Abundant Stock Items at Hand

Big Stock Capacity Guarantee (10000-Warehouse)

Various Logistics Option(DHL, TNT, Rail/Air/Sea Freight)

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What Industries Commonly Use Clamp Couplings and Why?

Clamp couplings are widely used in various industries due to their versatility, ease of installation, and ability to accommodate different shaft sizes and misalignments. Some of the industries where clamp couplings are commonly used include:

- Manufacturing: In manufacturing industries, clamp couplings are commonly employed in conveyor systems, machine tools, and material handling equipment. They provide a reliable and flexible connection between shafts, allowing for smooth power transmission and easy maintenance.

- Agriculture: Farm machinery and equipment often use clamp couplings to connect power take-off shafts, ensuring efficient power transfer from the tractor to various implements like mowers, balers, and harvesters.

- Food and Beverage: The food and beverage industry requires couplings that are easy to clean and maintain. Stainless steel clamp couplings are commonly used in food processing equipment due to their corrosion resistance and hygienic design.

- Packaging: Packaging machinery often uses clamp couplings to connect rotating components, such as rollers and conveyors, ensuring precise and synchronized movement during the packaging process.

- Oil and Gas: In the oil and gas industry, clamp couplings are used in various applications, including pumps, compressors, and drilling equipment. Stainless steel clamp couplings are favored in offshore and corrosive environments.

- Automotive: In automotive manufacturing, clamp couplings find applications in power transmission systems, steering columns, and drivetrain components.

- Marine: The marine industry often employs clamp couplings in propulsion systems and auxiliary machinery, especially when corrosion resistance and reliability are critical.

- Pharmaceutical: Pharmaceutical manufacturing equipment requires couplings that meet stringent hygiene standards. Stainless steel clamp couplings are suitable for pharmaceutical applications due to their cleanability and resistance to contamination.

- Mining: Mining machinery relies on robust and reliable couplings to withstand heavy loads and harsh operating conditions. Clamp couplings are commonly used in conveyors, crushers, and other mining equipment.

The widespread use of clamp couplings across industries can be attributed to their ability to provide a secure and backlash-free connection between shafts, accommodate misalignment, and handle varying torque and speed requirements. Additionally, their simple design and ease of maintenance make them a popular choice in numerous industrial applications.

Differences between Clamp Couplings Made from Different Materials

Clamp couplings can be manufactured from various materials, each offering unique characteristics and suitability for different applications. Here are the main differences between clamp couplings made from aluminum, steel, and plastic:

- Aluminum Clamp Couplings: Aluminum clamp couplings are lightweight and offer excellent corrosion resistance. They are often used in applications where weight reduction is crucial, such as in aerospace and automotive industries. However, aluminum has lower tensile strength compared to steel, making it less suitable for heavy-duty or high-torque applications.

- Steel Clamp Couplings: Steel clamp couplings are known for their strength and durability. They can handle higher torque loads and are well-suited for heavy machinery, industrial equipment, and power transmission applications. Steel couplings are available in various grades, and surface treatments can further enhance their corrosion resistance.

- Plastic Clamp Couplings: Plastic clamp couplings are lightweight and cost-effective. They are commonly used in applications where weight is a concern, and the torque requirements are relatively low. Plastic couplings may offer good chemical resistance and electrical insulation properties, but they may not be as durable as metal couplings and are not suitable for high-load or high-temperature applications.

Considerations: When selecting a clamp coupling material, consider the specific requirements of your application:

- Load and Torque: Choose a material that can handle the expected load and torque of your application without exceeding the material’s limitations.

- Environment: Consider the operating environment, including exposure to chemicals, moisture, and temperature fluctuations, to ensure the chosen material can withstand these conditions.

- Cost and Weight: Balance the cost-effectiveness and weight-saving benefits of materials like aluminum and plastic against the strength and durability of steel.

Ultimately, the material selection for clamp couplings should be based on the specific demands of the application to ensure optimal performance and longevity.

Can Clamp Couplings Accommodate Different Shaft Sizes and Materials?

Yes, clamp couplings are designed to accommodate different shaft sizes and materials, making them versatile for various mechanical applications. The flexibility in shaft size compatibility is one of the key advantages of using clamp couplings.

Clamp couplings typically come in a range of sizes, allowing them to fit various shaft diameters. The clamp design allows for easy adjustment and tightening around the shaft, creating a secure connection. This adjustability makes clamp couplings suitable for connecting shafts of different sizes without the need for precise machining or customizations.

Moreover, clamp couplings can handle different materials used for shafts, including steel, stainless steel, aluminum, and even non-metallic materials like plastics. As long as the shaft material is strong enough to handle the intended torque and load requirements, a clamp coupling can effectively connect the shafts.

When selecting a clamp coupling, it is essential to consider the specific application requirements, including torque, speed, misalignment, and environmental conditions. Properly matching the coupling size and material to the shafts’ specifications ensures a reliable and efficient connection, reducing the risk of premature wear or failure.

editor by CX 2024-03-18