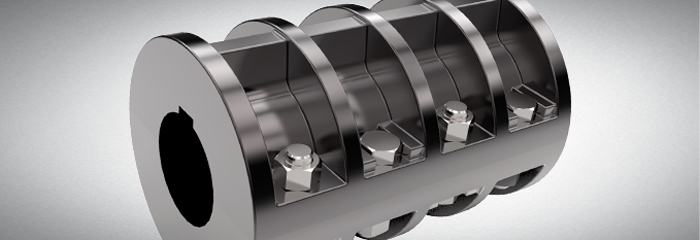

Product Description

Ductile iron grooved pipe fittings and couplings (FM and UL approved) mainly including 2 kinds of grooved products: (1) the pipe fittings function on connecting and sealing such as rigid coupling, flexible coupling, mechanical tee and grooved flange, (2) the pipe fittings function on connecting and transition such as bend, tee, cross, reducer.

| 1. Type: Grooved Elbow, tee, cross, reducer, cap, grooved coupling, mechanical tee, mechanical cross, flange adaptor … |

| 2. Material: Ductile Iron, ASTM A536, Grade 65-45 |

| 3. Certificates: FM & UL & CE |

| 4. Pressure rate: 1.6MPA &2.5MPA or 300PSI – 750PSI |

| 5. Connect type: Grooved-thread end & grooved end |

| 6. Size: 1″-16″ |

| 7. Finish: Paint, Epoxy or Galvanization |

| 8. Packaging: Wooden cases or pallets or as per customers’requirement |

| 9. Delivery Time: 25 days after order conformed |

| 10. Payment: By T/T or L/C |

| 11. Applications range: 1) Automatic sprinkler system for fire protection on commercial, civil and municipal constructions like water supplying, gas supplying, heat supplying etc 2) Industrial pipeline system on shipping, mine, oil field, textile, powder plant etc 3) Pipeline system on subway station, railway station, airport, seaport, bridge et |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can Clamp Couplings Be Used in High-Temperature or Corrosive Environments?

Yes, clamp couplings are designed to be versatile and can be used in a wide range of environments, including high-temperature and corrosive conditions. However, their suitability depends on the specific material and coating used in the construction of the coupling.

In high-temperature environments, clamp couplings made from materials such as stainless steel or high-temperature alloys are commonly used. These materials have excellent heat resistance and can withstand elevated temperatures without losing their structural integrity. It is essential to choose a clamp coupling with a temperature rating that exceeds the operating temperature of the application to ensure safe and reliable performance.

In corrosive environments where exposure to chemicals, moisture, or other corrosive substances is a concern, selecting a corrosion-resistant material is critical. Stainless steel clamp couplings, particularly those made from 316-grade stainless steel, are widely used in such conditions due to their superior corrosion resistance. For more aggressive corrosive environments, special coatings or surface treatments can be applied to further enhance the coupling’s resistance to corrosion.

It is essential to consider the specific requirements of the application when selecting a clamp coupling for use in high-temperature or corrosive environments. Factors such as temperature, humidity, exposure to chemicals, and the presence of abrasive substances should be taken into account. Consulting with coupling manufacturers or industry experts can help in choosing the most suitable clamp coupling for the intended application.

Use of Clamp Couplings in Horizontal and Vertical Shaft Applications

Yes, clamp couplings can be used in both horizontal and vertical shaft applications. The design of clamp couplings allows them to provide secure and reliable shaft connections in various orientations, making them versatile for different mechanical systems.

Horizontal Shaft Applications: In horizontal shaft applications, clamp couplings are commonly used to connect two shafts in a straight line. They are often employed in conveyor systems, pumps, fans, and other machinery where the shafts are aligned horizontally. The clamping action of the coupling ensures a rigid and balanced connection, transmitting torque efficiently from one shaft to another.

Vertical Shaft Applications: In vertical shaft applications, such as in vertical pumps, mixers, or gearboxes, clamp couplings need to support the weight of the connected components in addition to transmitting torque. The design of clamp couplings with robust clamping screws ensures that the coupling remains securely fastened even in vertical orientations.

Factors to Consider: While clamp couplings are suitable for both horizontal and vertical shaft applications, there are some considerations to keep in mind:

- Load and Weight: In vertical shaft applications, the coupling must handle the weight of the rotating components. It is essential to choose a clamp coupling with sufficient load-carrying capacity to support the vertical arrangement.

- Alignment: Proper alignment of the shafts is crucial for any coupling, but it becomes particularly important in vertical applications to avoid excessive loads and premature wear.

- Material and Environment: Selecting the appropriate material and surface treatment for the clamp coupling is essential, especially if the application involves exposure to harsh environments or corrosive substances.

Overall, clamp couplings are a reliable and cost-effective choice for various shaft applications, and their ability to perform well in both horizontal and vertical orientations makes them widely used in a range of industrial machinery and equipment.

Can Clamp Couplings Accommodate Different Shaft Sizes and Materials?

Yes, clamp couplings are designed to accommodate different shaft sizes and materials, making them versatile for various mechanical applications. The flexibility in shaft size compatibility is one of the key advantages of using clamp couplings.

Clamp couplings typically come in a range of sizes, allowing them to fit various shaft diameters. The clamp design allows for easy adjustment and tightening around the shaft, creating a secure connection. This adjustability makes clamp couplings suitable for connecting shafts of different sizes without the need for precise machining or customizations.

Moreover, clamp couplings can handle different materials used for shafts, including steel, stainless steel, aluminum, and even non-metallic materials like plastics. As long as the shaft material is strong enough to handle the intended torque and load requirements, a clamp coupling can effectively connect the shafts.

When selecting a clamp coupling, it is essential to consider the specific application requirements, including torque, speed, misalignment, and environmental conditions. Properly matching the coupling size and material to the shafts’ specifications ensures a reliable and efficient connection, reducing the risk of premature wear or failure.

editor by CX 2024-04-30