Product Description

ABOUT US

HangZhou Suijin machinery Technology Co,.Ltd is a profational manufacturer in HangZhou city, our main process is investment casting/precision casting and machining, for casting process, we have 2 kinds of production line, 1 is precision casting, another is water glass with competitive cost.

Apart from the investment casting workshop and machine workshop, we also provide the CHINAMFG parts to meet the requirement for varial demand from our customer.

CERTIFICATIONS

Our company got the ISO9001 and IATF16949 certification, and aslo we are awarded the new high-tech enterprice by Chinese government, and we have more than 20 patent.

ADVANTAGES

• More than 10 years experience on casting and machining

• Advanced inspection equipment to ensure the tolerance

• Flexible PO QTY to meet customer demand

• Professional engineers in casting and machining

• Competitive price and exllent parts quality

• Nearby HangZhou port, on-time delivery

PROCESS FLOW

OEM&ODM SERVICE

HangZhou suijin machinery technology can provide the ODM&OEM service for customer, and main is ODM, we can manufacturing the customized parts according to 2D&3D, we have professional R&D team can take part in ealier development phase of the project.

AVALIABLE MATERIA & SURFACE TREATMENT

| Avaliable Material | |||

| Carbon Steel | Alloy Steel | High Chromium Cast Iron | Low carbon steel |

| Stainless Steel | Duplex Stainless Steel | Steel bar | Ductile Cast Iron |

| Surface treatment | |||

| Heat Treatment | Zinc Coating | Blackening | Mirror Polishing |

| Satin Polishing | Electrolytic Polishing | Shot Peening | DACROMET |

PRODUCT APPLICATION

AUTO PARTS

• Exhaust inlet/outlet cone • Shift sleeve • Fuel rail bracket

• Tempreture sensor boss • Mounting Brackets • Oxygen sensor boss

• Brake balance block • EGR sensor boss • Exhaust valve body

ARCHITECTURAL HARDWARE

• Mounting Base • Mounting plate • Bearing Covers

• Coupling • Grount sleeve • Sprockets

• Handle • law glass curtain wall accessories • Side Plates

AGRICULTURAL MACHINERY PARTS

• Tooth Blocks • Track shoes • Bucket Teeth

• Track Links • Clamping • Mounting Brackets

• Lifting Eyes • Quick Joint • Trencher Tooth

MARINE HARDWARE

• Star handle • Door hinge • Folding Dock Cleat

• Mirror Polished Mooring • Hollow base boat rope cleat • Mounting Brackets

VALVE/PUMP

• Valve body • Explosion-proof valves • Pipe fitting

OTHERS

The casting part is wildly use in the industries, such as rail&transit parts, bicycle parts, casting impeller, food machine sorting components, solar mounting system parts, container safety parts, Electronic lock body, robot parts and so on, we have more than 20 patents related to this kinds of project in production.

ADVANCED EQUIPMENTS

Our company also equiped advance inspection equipment to meet the inspection requirement of the parts, so that we can sure the part can have a good quality.

MAIN EQUIPMENT LIST

| Magnetic defect inspection | Spectrometer | HB hardness inspection | Mechanical inspection |

| Ultrasonic defect inspection | Roughness tester | HR hardness inspection | CMM inspection |

| Metallographic detector | X-ray inspection | Dye penetrant inspection | 100% Thread inspection |

FAQ

| Q1 | Are you factory or trading company? |

| A1 | We are factory located in HangZhou city, China |

| Q2 | What kinds of language is avaliable? |

| A2 | English, Chinese, except email cummunication, we are ok with video meeting and calling. |

| Q3 | How should I place an order? |

| A3 | We are receive the PO and production drawing by email. |

| Q4 | Which shipping methed is ok for you? |

| A4 | Normally shipping by sea and train is use for mass production order delivery. DHL,TNT,FedEx, UPS,EMS air shipment is use for sample delivery. |

| Q5 | How can I contact you? |

| A5 | You can contact us by email, and also we can chat by Skype, Teams, WhatsApp, Facebook. |

| Q6 | What kinds of drawing format can be use? |

| A6 | PRO/E, Auto CAD, CHINAMFG Works, IGS, UG, CAD/CAM/CAE, STEP. |

| Q7 | Which packing material do you use for sea shipping? |

| A7 | For sea shipping, we will packaging with European standard wooden pallet. The parts will packing with PE bag inside the carton box. |

| Q8 | How do you deal with the RFQ? |

| A8 | Sales receiving the RFQ—Feasiblity study meeting with R&D engineer—Feed back technical issues with Customer—Sales quoted |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

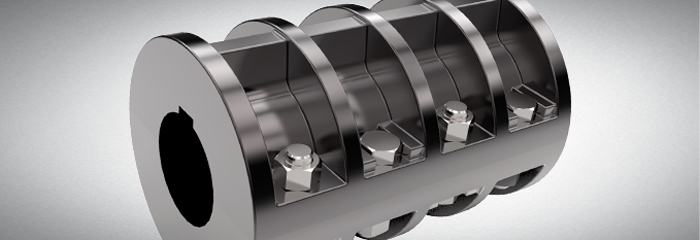

Are There Any Maintenance Requirements for Clamp Couplings to Ensure Their Longevity?

Yes, like any mechanical component, clamp couplings require regular maintenance to ensure their longevity and optimal performance. Proper maintenance can help prevent premature wear, reduce the risk of failure, and extend the service life of the coupling. Here are some essential maintenance practices for clamp couplings:

- Regular Inspection: Perform visual inspections of the clamp coupling regularly to check for signs of wear, damage, or misalignment. Look for cracks, corrosion, or any deformation in the coupling components.

- Lubrication: Some clamp couplings may require periodic lubrication to reduce friction between moving parts. Check the manufacturer’s guidelines for the appropriate lubrication schedule and use the recommended lubricant.

- Bolt Tightening: Ensure that all the bolts and screws securing the clamp coupling are properly tightened according to the manufacturer’s specifications. Loose bolts can lead to misalignment and coupling failure.

- Alignment: Regularly check the alignment of the connected shafts. Misalignment can cause excessive stress on the coupling and lead to premature wear. If misalignment is detected, it should be corrected promptly.

- Environmental Protection: If the clamp coupling is used in harsh environments, take measures to protect it from dust, debris, and corrosive substances. Use suitable covers or guards to shield the coupling from external contaminants.

- Load Monitoring: Be aware of the operating conditions and load requirements of the machinery. Excessive loads or shock loads can impact the performance of the coupling. Avoid exceeding the coupling’s specified torque and speed limits.

- Regular Replacement: Even with proper maintenance, clamp couplings have a finite service life. It is essential to follow the manufacturer’s recommendations for replacing the coupling at the end of its expected lifespan or if any significant wear or damage is detected.

By following these maintenance practices, operators can ensure that the clamp couplings remain in good condition and continue to function reliably. Regular maintenance not only extends the coupling’s lifespan but also enhances the safety and efficiency of the entire mechanical system. Always refer to the manufacturer’s guidelines and instructions for the specific maintenance requirements of the clamp coupling model used in the application.

Clamp Couplings and Damping Vibrations/Noise

Yes, clamp couplings can help dampen vibrations and reduce noise in mechanical systems to some extent. While not specifically designed as vibration isolators, clamp couplings can mitigate vibrations and noise due to their unique design and material properties.

The design of clamp couplings involves a split hub with screws that securely fasten around the shafts. This design offers several benefits:

- Damping Effect: The material of the coupling can absorb and dampen some of the vibrations generated by rotating equipment. Elastomeric elements or flexible materials used in some clamp couplings can help attenuate vibrations.

- Reduction of Resonance: Vibrations in rotating machinery can sometimes lead to resonance, causing excessive oscillations. Clamp couplings can help break the resonance cycle and prevent amplification of vibrations.

- Torsional Compliance: Some clamp couplings exhibit a degree of torsional compliance, which means they can tolerate small angular misalignments and dampen torsional vibrations.

- Transmissible Torque Variation: In some cases, clamp couplings can absorb torque spikes or variations, reducing the impact of sudden changes in load.

While clamp couplings can provide some level of vibration and noise reduction, their primary function is to transmit torque and accommodate misalignment between shafts. For more demanding vibration isolation or noise reduction applications, specialized components such as flexible couplings with damping features or dedicated vibration isolation mounts may be more suitable.

It is essential to consider the specific requirements of the mechanical system and consult with experts to determine the most appropriate coupling or isolator for achieving the desired level of vibration and noise reduction.

Advantages of Using a Clamp Coupling

A clamp coupling offers several advantages compared to other types of couplings, making it a popular choice in various mechanical systems:

- Easy Installation: Clamp couplings are simple to install and require minimal tools and expertise. The design allows for quick assembly and disassembly, making maintenance and shaft replacement convenient.

- Cost-Effective: With a straightforward design and fewer components, clamp couplings are cost-effective to manufacture and purchase.

- High Torque Transmission: Clamp couplings can handle high torque loads, making them suitable for heavy-duty applications in industries like manufacturing, mining, and construction.

- Zero Backlash: The clamping mechanism ensures a tight fit between the shafts and the hubs, resulting in zero backlash. This feature is vital for applications that require accurate and precise motion transfer.

- Flexibility: Clamp couplings can accommodate different shaft sizes and materials, providing flexibility in system design and shaft compatibility.

- Compact Design: The compact and lightweight design of clamp couplings makes them ideal for applications with space constraints.

- No Lubrication Needed: Unlike some other couplings, clamp couplings do not require lubrication, reducing maintenance requirements and eliminating the risk of leakage or contamination in certain environments.

- High Misalignment Tolerance: Clamp couplings can handle moderate levels of angular, parallel, and axial misalignment, ensuring reliable operation even when shafts are not perfectly aligned.

- Reduced Downtime: The ease of installation and maintenance of clamp couplings contributes to reduced downtime during equipment repairs or replacements.

Due to these advantages, clamp couplings are widely used in various industries and mechanical setups for their simplicity, reliability, and cost-effectiveness in transmitting torque and rotational motion between shafts.

editor by CX 2024-05-06