Industrial SU Sort

The SU Style coupling features

for making a floating shaft coupling. The shaft can be hollow for prolonged light weight floating shaft couplings.

Industrial SX Variety

This is certainly the conventional coupling type that includes two hubs, a stock length spacer made to meet sector standard lengths, and two unitized disc packs. The coupling has two flex planes, one at every single disc pack, making it possible for this coupling to accommodate parallel, angular, and axial misalignment with specified limits. The coupling is available in 6 and 8 bolt models and bore sizes as much as 13 inches (330mm) to the greatest dimension. Customized spacer lengths might be produced to meet special shaft separations essential for distinct applications. The SX coupling is usually fitted with overload bushings to safeguard the disc packs in in excess of torque problems and can act as an anti-flail gadget. SX couplings are assembled at the time of installation over the tools where the coupling are going to be in services.

Industrial DI Style

The DI Type coupling includes a “Drop-In” spacer assembly that is definitely assembled on the factory. The coupling includes two hubs and a spacer assembly comprising from the spacer, two unitized disc packs, and two guard rings. The disc packs are bolted for the spacer and guard rings at the factory making use of the torque values proposed by Lovejoy for your disc pack bolts. Together with the hubs mounted on the shafts, the complete disc pack assembly is often “Dropped In” spot concerning the 2 hubs. The hubs are piloted to make sure proper centering from the spacer assembly. This piloting serves as an anti-flail function and aids within the coupling’s potential to meet the stability specifications mandated by API. This fashion coupling is developed to meet the stability and anti-flail prerequisites specified in API-610.

Oversized, or Jumbo, hubs can be found for use with the DI Sort coupling to allow for larger bore sizes on most DI coupling sizes. This enables to the utilization of smaller DI couplings in applications where a smaller size coupling can still accommodate the application torque.

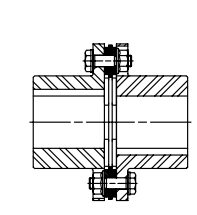

Industrial SXC Form

The SXC Form is definitely the near coupled variation of your SX Variety coupling. The SXC is just like the SX coupling in that the disc packs are attached once the coupling is set up. During the near coupled units, the hubs are turned inward and are mounted inside the spacer. Note that together with the hubs inside the spacer, the maximum bore permitted within the hub will likely be decreased. The SXC couplings can be used with one particular or each hubs turned outward to allow the coupling to accommodate diverse shaft separations.

Industrial SXCS and SXCST Forms

The SXCS and SXCST Types have split spacers plus the disc packs can be serviced or eliminated without the need of moving the hubs within the shafts and without moving the equipment. The SXCS Style has the bolts that connect the hubs towards the split spacer installed from your ends of the couplings. The SXCST possess the bolts put in from within the spacer pointing outward in direction of the hubs.

Supplemental Types